CEVİZ KABUĞU RAMATI

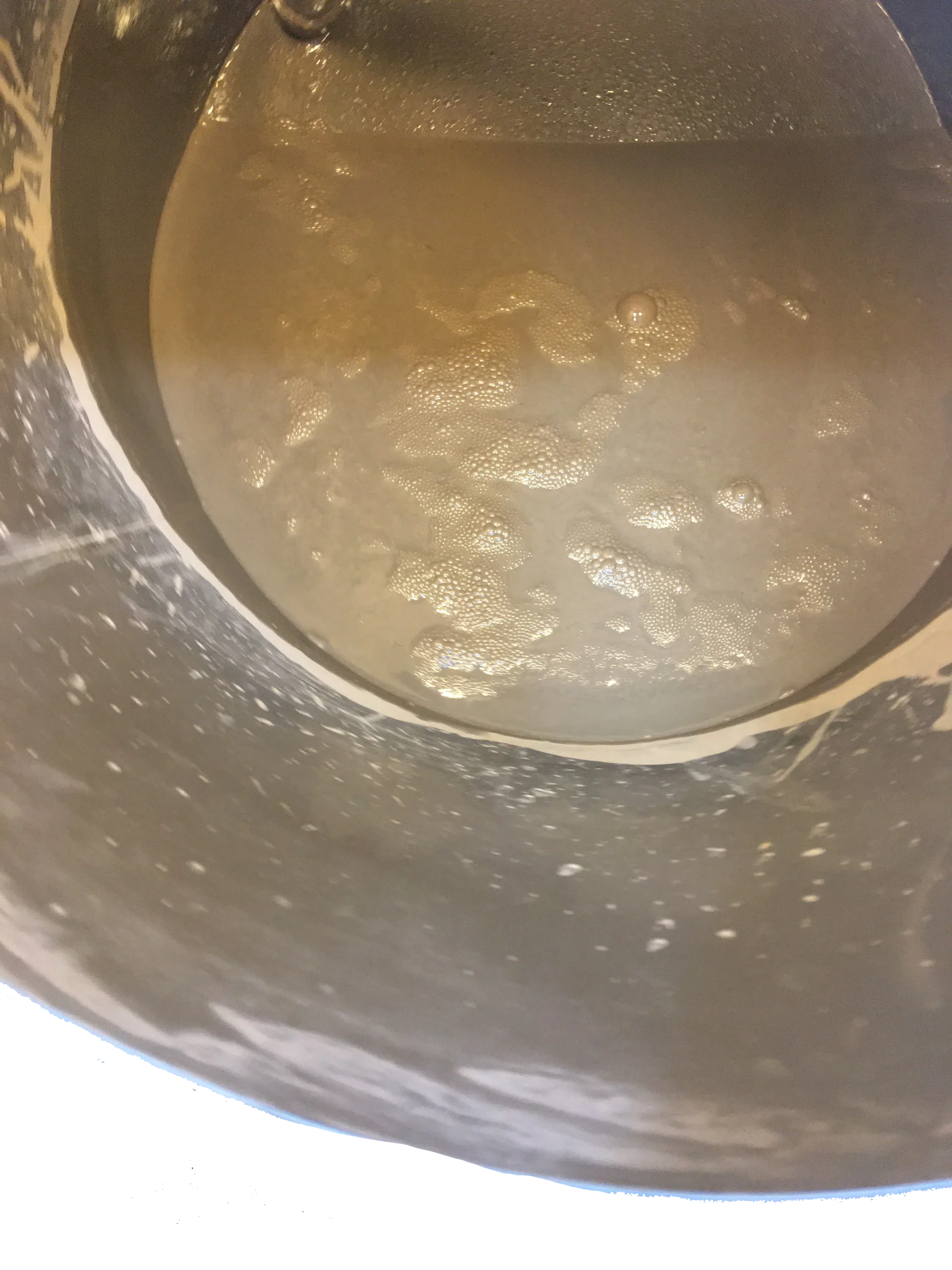

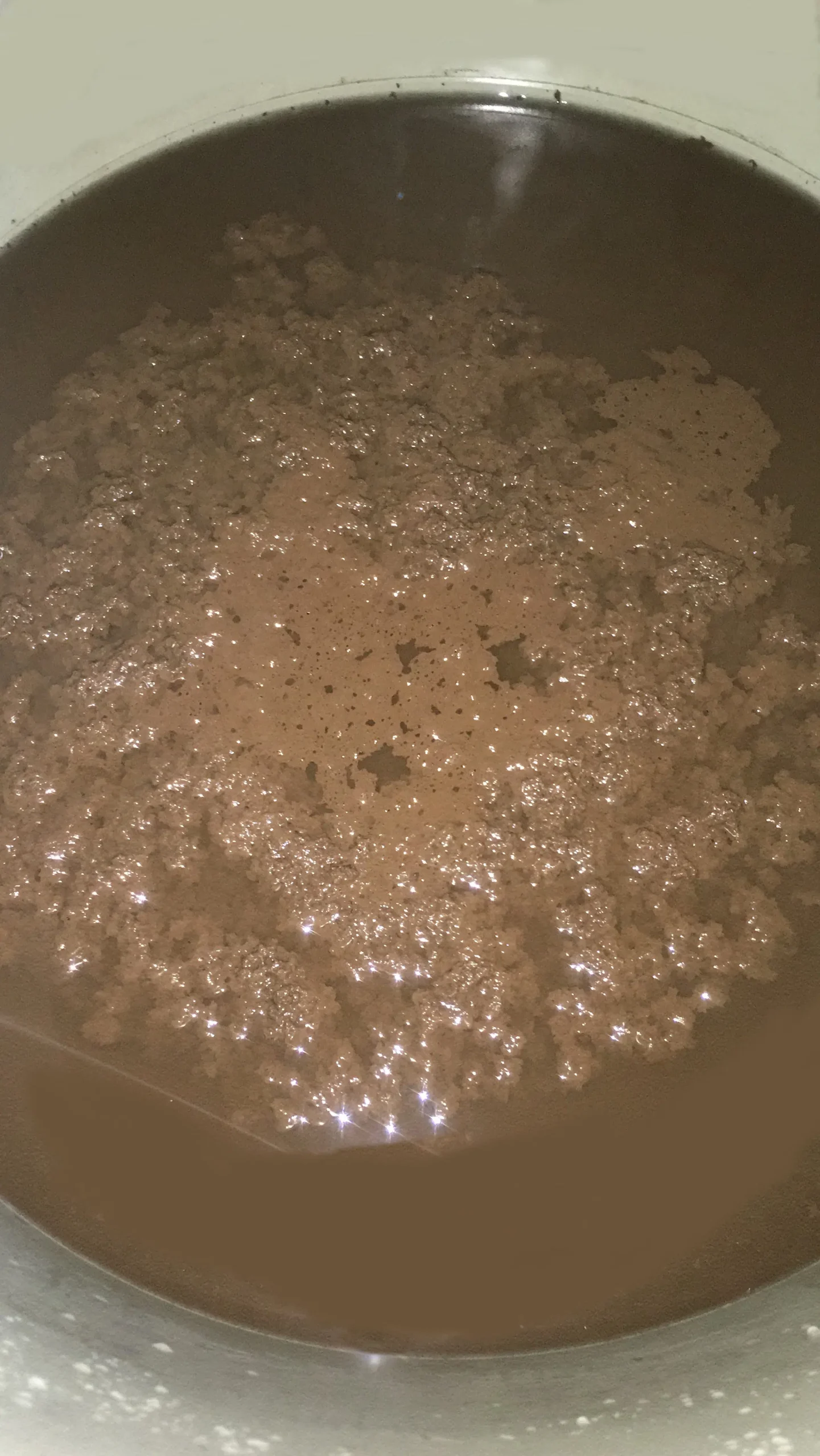

Ceviz kabuğu kalorisi en yüksek ağaçlardan birisidir. Yavaş yanması, kül hale getirilip geri kazanım sürecinde biraz uzun sürmektedir. Kapalı bir fırın içerisinde elektrikle ısıtılması en yüksek verimi almamıza olanak tanır. Daha sonrasında küllerden kimyasal geri kazanım ile süreç tamamlanır.

CEVİZ KABUĞU RAMAT SİSTEMİ

Nasıl Yapılıyor Diyorsanız

Bizimle İletişime Geçin